Microcontrollers (MCUs) are crucial in our daily lives, serving as essential

components in various home appliances, consumer, industrial, and vehicle

electronics. However, the most significant difference between industrial-grade

MCUs and consumer-grade MCUs is the different quality requirements: The

industrial-grade MCUs require higher product stability, reliability, and

consistency, and calls for more robust antistatic capabilities, better

resistance to surge voltage and surge current, extended operating temperature

range, and longer service life. These are also regarded as must-have "hard

indicators" of "high-quality MCUs" by Eric Jin, GigaDevice’s Product Marketing

Director.

1. Four Major Standards of High-Quality MCUs

Since 2013, GigaDevice has expanded its GD32 MCU family product portfolio to encompass 41 series and more than 500 part numbers in a decade. By focusing on the Arm core, GigaDevice has successfully established a comprehensive MCU ecosystem that fully covers the high-end, mainstream, and entry-level markets, continuing to strengthen the ability and foundation to serve customers in the general market. Mr. Jin highlights GigaDevice's continuous efforts in assessing and gauging the diverse requirements arising from various application scenarios in the industrial market, aiming to develop top-tier, high-standard MCU products.

√ Extended Operating Temperature Range

Typically, consumer-grade MCUs are designed to operate effectively within the temperature range of 0°C to 70°C. In contrast, all GD32 MCU products belong to the industrial-grade category, engineered to function flawlessly in a much broader temperature span of -40℃ to 85℃, with the potential for extension up to 105℃. The operating temperature range for automotive-grade MCUs spans from -40°C to 125°C. In this environment, the chips exhibit stable performance for durations exceeding 10 to 15 years, effectively mitigating the risk of critical malfunctions that could trigger a complete system shutdown.

√ Robust Electro-Static Discharge (ESD) Protection and High Interference Immunity

ESD is generally considered the biggest potential killer of electronic product quality. Consequently, ESD protection has become a pivotal part of electronic product quality control. Discrepancies in ESD protection design across related products mirror the enterprise's positioning and the level of reliability embedded in its design.

√ Lower Failure Rate

High-quality MCUs are mainly used in the industrial control, home appliances, and automobile fields, and the requirements for chip quality are high due to the long product iteration cycle. The failure rate is usually lower than 100ppm, far beyond the standard of common consumer-grade MCUs. In addition, high-quality MCUs incorporate the functional security design concept, which supports functional protection, such as overcurrent and overvoltage protection, and security functions, such as encryption and error correction.

√ Excellent Stability and Consistency

Under the strict management of quality standard systems, the same batch of products is guaranteed to have the same stability and consistency when they leave the factory. This uniformity safeguards optimal functionality across complex and harsh application scenarios. Throughout the stages of development, manufacturing, storage and transportation, and client application, GigaDevice's fault analysis (FA) team systematically dissects potential defects' root causes. The insights gained from these analyses are then applied to each facet of the process, improving product quality and reliability.

The more challenging aspect is that the above four requirements often co-exist in actual application scenarios. If an MCU manufacturer fails to have a solid technical foundation, rich application scenario verification experience, and a clear strategy for continually iterating on product reliability and security technologies, it will be difficult for the manufacturer to obtain sustainable development momentum within the industry.

2. Building Excellent Original "Soft" Power

For the general MCU industry, in addition to evaluating whether an MCU manufacturer has sustainable new product development capabilities, customers also value the original manufacturer’s "soft" power, encompassing various attributes: R&D investment capabilities, quality control capabilities (yield, product consistency, and reliability), quality system construction, pre-sales, and after-sales service support within the product life cycle, and stable supply guarantee capabilities.

Therefore, although the standards for identifying high-quality products are available, how to design, manufacture, and screen high-quality MCUs has become GigaDevice’s most pragmatic challenge. "Managing the entire production process of high-quality MCU products is divided into three levels. For IC design companies, the quality management of the design and verification aspects in the initial stage is of utmost importance." Mr. Jin revealed that, with the help of a series of methods such as optimization design, sensitivity analysis, and computer simulation, the R&D engineers could engage in the first step towards improving yield by analyzing and predicting the possible failure modes of the chips in advance and adopting corresponding solutions to avoid them.

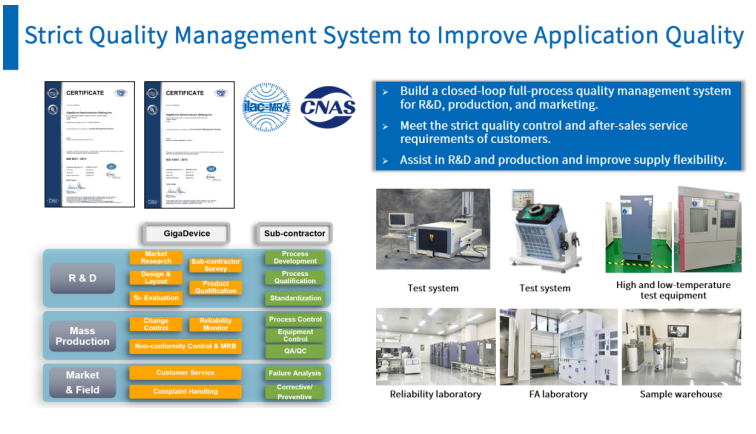

At the process level, through cooperation with mainstream fabs and OSATs (outsourced semiconductor assembly and testing), GigaDevice guarantees technological advancement and production reliability. Considering the high reliability and low defect requirements of industrial equipment or automotive components, industrial-grade/automotive-grade MCUs shall be specifically designed and screened in terms of functionalities such as high-precision clocks and self-calibration functions in harsh application environments before they leave the factory. For this purpose, GigaDevice has invested in the construction of an independent testing laboratory certified by CNAS (China National Accreditation Service for Conformity Assessment) and ILAC (International Laboratory Accreditation Cooperation), which can be engaged in a series of reliability tests, including high and low-temperature impact tests, electrical characteristics tests, failure analysis, and EMI anti-interference tests, and can provide 7*24 testing and calibration services in accordance with international standards. This ability is unmatched by many manufacturers and is also the foundation for GigaDevice to serve global customers.

Since 2008, GigaDevice has been certified by the International Organization for Standardization (ISO) successively in accordance with the Quality Management System (ISO 9001) and the Environmental Management System (ISO 14001). In the field of automotive quality management systems, GigaDevice follows the IATF 16949 standard, and its functional security management system has also obtained the ISO 26262 ASIL D standard certification issued by TÜV Rheinland and meets the strict requirements of the automotive application field. GigaDevice is also certified by DUNS of Dun & Bradstreet.

Thanks to these certifications, GigaDevice has established branches in Europe, the United States, Singapore, Japan, South Korea, and other regions in recent years. Its related international service capabilities, such as product planning, mass production scale, quality system, delivery efficiency, technical support, and service support, have been greatly enhanced, and its demand share of well-known international customers has increased year after year.

At the same time, considering that the semiconductor industry is highly cyclical, GigaDevice has also implemented a supply chain strategy of multiple production line resources to ensure a stable supply. Both the frontend fabs and the backend OSATs can carry out domestic/overseas diversified and simultaneous production to ensure the maximum and flexible production capacity.

With intensified market competition and fluctuating supply cycles in recent years, an industry-wide issue has arisen where substandard chip products are sold as high-quality goods without reliability verification through three-temperature testing and failure analysis. The abnormality of these defective chips may not be detected in the functional test stage, and the problem will not be discovered until the customer mass production officially starts, which may lead to serious quality control risks and even recall losses. With strict quality management commitments, GigaDevice provides reliable, high-quality MCU products to the market and serves more and more global brand customers with strategic cooperation intentions, increasing its market share.

3. Application of high-quality MCUs

The application of high-quality MCUs with extended temperature ranges is far more extensive than commonly perceived, encompassing sectors such as new energy, data centers, home appliances, industry, LED lighting, digital power supplies, encoders, motor drives, and automobiles. While these products may entail heightened costs, they serve as indispensable safeguards against potential calamities in demanding environments, where even minor glitches could precipitate catastrophic incidents.

√ Industry

As the low-carbon development strategy has become a national strategy, the new energy power system represented by wind power, photovoltaic, hydropower, and new energy storage technology is rapidly rising as China's main body of energy structure. Data shows that growth of at least 720 million kilowatts is required in the next ten years for the wind power and photovoltaic industries to achieve the goal of a total installed capacity of 1.2 billion kilowatts in 2030. The China Photovoltaic Industry Association predicts that during the "14th Five Year Plan" period, the average annual newly installed capacity of photovoltaic in China is generally expected to be 70 million kilowatts, and the optimistic estimate is 90 million kilowatts.

Another industry that will develop rapidly with wind and photovoltaic power generation will be the energy storage system (ESS). Data shows that in the next two decades, global investment in new energy storage is expected to increase by USD 620 billion, and between 2020 and 2025, the energy storage market will grow at a compound annual growth rate (CAGR) of 24%. The residential market will account for the largest energy storage market share.

As an indispensable key component in photovoltaic inverters and energy storage converters, GD32 MCU has been widely used in various fields, including inverter control, data monitoring, communication transmission, human-machine interaction (HMI), arc test and quick shutdown, efficiency optimization, BMS monitoring and protection, and photovoltaic accessories. The rising trend in GigaDevice's MCU market share serves as clear evidence of its industry recognition. This acknowledgment becomes especially significant when considering the demanding requirements for prolonged temperature endurance, reliability, and robustness in specialized outdoor application scenarios.

√ Home Appliances

MCUs applications in home appliances include refrigerators, air conditioners, washing machines, and kitchen appliances. MCUs can control home appliances' power, temperature, humidity, and operating status. They should be characterized by traits such as high reliability, low power consumption, support for multiple communication protocols and interfaces, compact size, and cost-effectiveness.

According to Omdia data, the global home appliance market's MCU revenue reached USD 1.67 billion in 2022 and will grow at a CAGR of 7.3%. The market size is expected to reach USD 2.37 billion in 2027.

As a core indicator of high-quality chips, the "failure rate" is especially important in the home appliance market, where the unit price of a home appliance can be quite expensive. With its industry-leading low failure rate, GD32 high-quality MCU guarantees stable product performance in complex and diverse application scenarios, and its strong anti-electromagnetic interference capability further improves the stability of home appliance operation. In addition, GD32 MCU meets the IEC 60730 Class B functional security standard and has obtained test reports and certificates issued by third-party organizations such as UL/SGS. GigaDevice provides certified software self-test libraries and complete safety documents to help customers launch home appliances that meet safety regulations quickly.

√ Lighting

LED display and lighting is another industry that values MCU quality requirements.

From the realization of lighting to the subsequent control of lighting and ultimately to the realm of intelligent lighting, the landscape of lighting technology has constantly changed. LED lighting has become the mainstream of today's home illumination, while intelligent lighting has become the first choice and entry point for the new ecosystem of whole house intelligence. According to the statistics from the LED Research Institute of GGII, the output value of China's LED lighting market has increased from RMB 301.7 billion in 2016 to RMB 582.5 billion in 2021, and the average CAGR reaches 14.95%.

In the future, lighting will go through technological innovations in terms of period control, ambient brightness sensors, motion sensors, and heat management. For MCUs, the lighting market demands will be manifested in the following aspects: precise control of current and extended lamp life; multiple protection functions that ensure lamp safety; high integration that saves space and cost; flexible and precise dimming that consumes less energy at the same brightness; diversified communication methods; and operating temperature up to 105°C.

√ New Infrastructure

With the implementation of the "East Digital West Computing" strategy in China, data centers, optical fiber communication, 5G base stations, and other industries will usher in rare development opportunities. Optical modules are poised to experience a significant surge in market demand as the most important components. On the one hand, the communication optical modules in existing domestic data centers are still dominated by 100Gbps. They are evolving to the more expensive 200G/400G, while the overseas optical modules have had an updated trend of 800G. According to Yole's estimation, driven by the construction of 5G and data centers, the optical module market size is expected to reach USD 17.7 billion by 2025.

As the first Chinese manufacturer who has launched two series and six models of products in the optical module field, GigaDevice believes that domestic MCUs will have more advantages in terms of performance and cost. For the above markets, GigaDevice has also launched specific models of high-quality components with an extended temperature range (-40°C to +105°C) to support them. Currently, GD32E501 series MCUs have been able to cover the medium-speed and high-speed optical module markets. They are applicable to the development requirements of 100G/400G optical module products and can be widely used in 5G base stations, high-speed data centers, cloud servers, and other markets.

High-quality, high-temperature MCU products in the above application fields have been monopolized by leading international manufacturers all along. However, with the rise of Chinese manufacturers represented by GigaDevice, combined with the agile, flexible, and fast response capabilities, as well as localized service and cost advantages, related products offer complete coverage and have reached the international first-class standard in certain individual fields. Conversely, GigaDevice's current performance growth is primarily attributed to its presence in diverse markets, including industry, energy, energy storage, and automotive sectors. Taking into account the fundamental principle guiding the company's product development and strategy, which centers around "bridging the technology realm with the physical world," this approach has, to a certain extent, contributed to mutual success alongside the advancement of high-quality MCUs.

4. Conclusion

The ethos "Everyone is a quality person" is inscribed on GigaDevice's official website and is deeply rooted at the core of the company's culture and the heart of every GigaDevice team member. This principle has evolved into GigaDevice's modus operandi, guiding the rigorous quality management process and comprehensive oversight from the inception of product design to its utilization by customers. This commitment ensures constant product reliability across its lifecycle while meeting customer expectations at every juncture. This ethos embodies GigaDevice's unwavering dedication to delivering exceptional quality and customer satisfaction.